Mobility Group

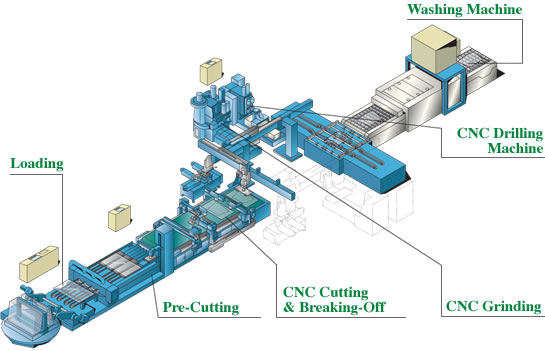

Equipment, machinery and systems for manufacturing automotive fabricated glass CNC-cutting machines, drilling machines, beveling machines, and automatic handling systems.

Electronics & New business development Group

At Electronics and Strategic business of AGC Group companies, we provide integrated service such as planning, design, equipment procurement, construction management, and start-up support.

Tooling group

- ●Molds, jigs and other tooling for manufacturing automotive glass

- ●Supporting the AGC Group as it introduces equipment in its global expansion

- ●Design ability using 3D CAD/CAM

- ●The advanced technical abilities in mold design and manufacturing, to realize the customer's vision.

- ●The ability to use foreign companies to produce and deliver goods overseas, including import/export work.

- ●Developing human resources to build linguistic abilities through overseas experience.

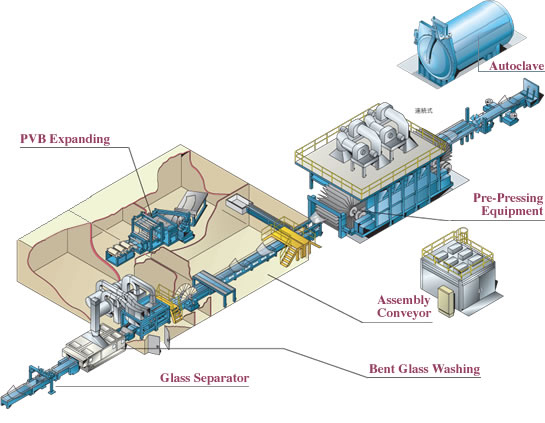

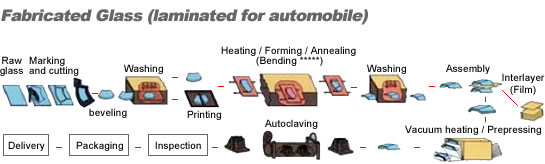

Fabricated Glass (laminated for automotive)

[Pre-process for Automotive Glass]

[Post-process for Windshield]

Robot Grinding Machine

Robots achieve high-quality chamfering

- ●High-quality grinding

- High-rigidity longitudinal grinding machine produces high-quality grinding to maximize the effects of water cooling.

The fabricating water collecting function prevents the scattering of the water. That makes maintenance easier and lengthens equipment lifespans. - ●Space saving and automation

- Use of compact robots for handling saves space and labor.

- ●Offline teaching system

- A dedicated data creation system makes it possible to create glass shape data for robot grinding quickly, on a computer, with absolutely no robot teaching.

- ●Adaptable to FA

- Data can be centrally managed over a network, and applied to FA for a factory.

That is ideal for high-variety and small-lot production.

Bent glass washing and drying machine

High-pressure water cleaner

- ●High-pressure water cleaning

- Bonding surfaces are washed with high-pressure spray.

Purified water is used to stabilize film bond strength. - ●Drainage and drying

- Nozzles are used to adapt to various shapes.

- ●Separating

- Sheets are separated automatically from one pair of glass sheets. This saves labor and ensures safety.

Continuous pre-pressing device (high-productivity pre-pressing device)

- ●Support for high productivity

- All handling can be automated, to save labor.

- ●Maintaining high quality

- Rubber bags are used to enable high-quality bonding to difficult shapes.

- ●No job changes required

- Whatever the glass size or shape, there is no need for job changes, and diverse shapes can be handled.

Film extender

Smooth shade band

- ●High quality

- Film is hot rolled uniformly, and then cold hardened uniformly, to enable smooth extension with little distortion or irregularity. The margin of contraction after extension is stable.

- ●Small-lot, high-quality production is possible

- ●Various film types are supported

- It can be used for refrigerated film.

Molding technology fields with experience

Hot glass bending molds, jigs for air-cooled glass strengthening

Glass sucker handling

Cast material: SUS304 FCD weight: ~800kg

Plastic mold fabrication: Gun drill hole penetration length ~ 1,000mm [φ16mm]

Surface treatment (cermet, etc.)